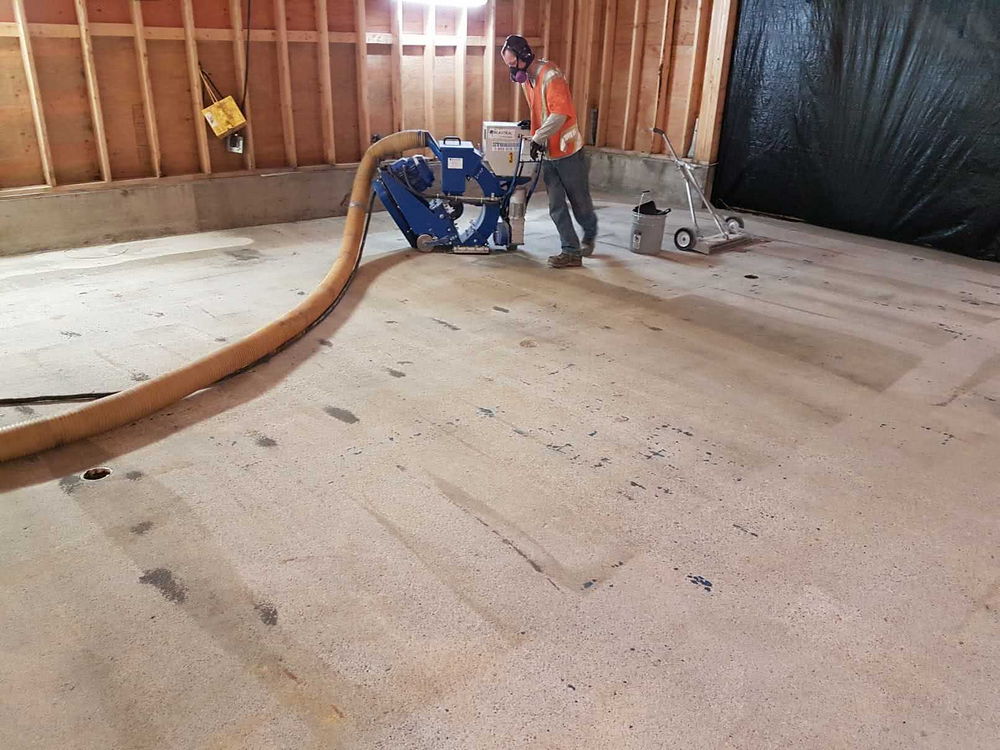

Epoxy & Urethane Concrete Floor Coating at Carmaq Processing Plant

The concrete floor resurfacing job at the Cermaq processing plant was important for several reasons. It’s a fish processing plant for farmed salmon here in British Columbia. That means heavy equipment, cleaning agents, lots of boots, and lots of potential for slippage.

Why Cermaq Needed a Urethane Concrete Floor Coating

If you’ve ever been to a brewery or processing plant, you know what the floor can be like. It’s very easy to slip, and the potential for injury is high, to say the least. You’re certainly at risk for cuts and spills, but on the wrong floor, in the wrong conditions, a worker could conceivably slip and injure themselves.

No one wants to go there. And it’s why we felt a combined epoxy floor with a urethane coating, in this situation, was the way to go.

Urethane Coating Has Good Slip Resistance

Urethane coating was a good choice for Cermaq. Urethane has good slip resistance, which, ideally, should help reduce some of the nasty tumbles its workers might otherwise take in a factory setting with water and fish oils ending up on the floor. Fish oil might be healthy for you, but on the floor, not so much!

Cermaq uses chemicals as part of its daily cleaning, too. And that heavy equipment and the boots worn by its workers were no friend of the floor either.

New Concrete Floor Coating, New Start

Once again, the urethane concrete floor coating proved to be an excellent choice for Cermaq. As you can see from the pictures we took, the floor now has a much more vibrant appearance. The combined epoxy flooring with the urethane coating gives it good abrasion resistance and protection from humidity.

It’s less slippery than it was before – a big factor for the workers and their peace of mind.

All in all, this was a very important project for Cermaq. We were glad to help!